Industrial Marketplace Digitization

The consumer marketplace has been digitized from end to end. And the effects of digitization are still felt across this marketplace’s different facts, including leaderships, businesses, and technology transformations. Today, look at any industry – travel, retail, advertising, and entertainment – and you will see the full effects of digitization. In fact, digitization has been at the helm of core globalization.

And, now, digital has been all set to transform the industrial marketplace at an incredible velocity. This velocity is expected to be way faster than what we saw when digitization was changing the consumer marketplace for the better.

The number of connected assets, the amounts of economic values, and the wins that a digitized industrial ecosystem will deliver are yet unknown. But the transformation that digitization will have on the industrial marketplace’s financial landscape will be unimaginable.

And the next tectonic shift for industrial services will rely on digital twins that will help forecast the health and future of every physical asset. How will the industrial service providers do this level of forecasting accurately? They will use digital twins.

Understanding Digital Twins

As the name suggests, a digital twin represents a system or object and its lifecycle. A digital twin is also updated using simulation, real-time data, reasoning, and ML. Basically, an industrial service provider will use digital twins to help improve the quality of decision-making.

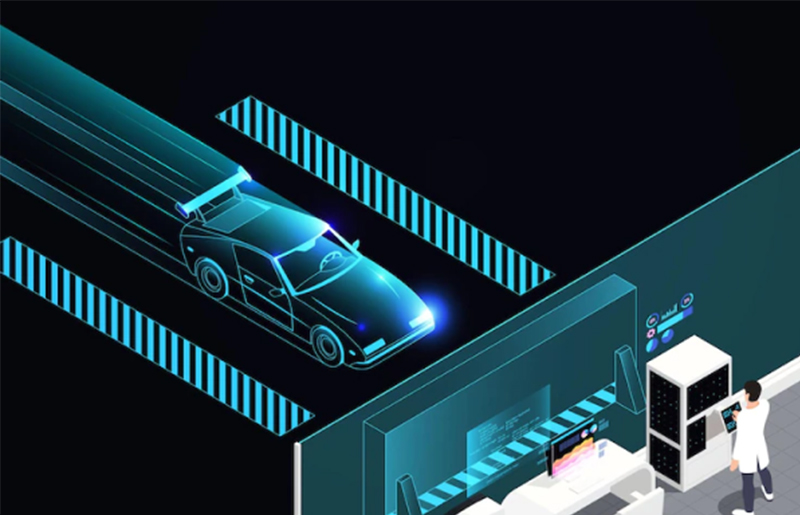

All in all, a digital twin is a robust virtual model that is engineered to reflect any physical object. This object is usually studied for optimizing its performance and proactively addressing its bottlenecks. The object whose digital twin is prepared is usually equipped with multiple sensors. Every batch of sensors attached to the object helps shape up its virtual model or digital twin.

A Digital Twin In Action

Here is a case in point for a digital twin. Suppose your business has attached multiple sensors to a wind turbine. Then those sensors will, of course, populate the turbine’s digital twin with multiple data points. These datasets will usually be related to the machinery’s weather conditions, temperature, energy output, etc.

In fact, these data streams help process the turbine’s digital copy that the analysts can study to gain more actionable insights into the machinery. And once the digital twin is informed with data, analysts will run multiple simulations, generate possible improvements, and study real-time performance issues in the turbine. The end result? Thanks to analyzing the machinery’s digital twin, your business will help build a more serviceable wind turbine.

Digital Twins + Metaverse = Infinite Growth Possibilities

Digital twins fall under the metaverse. If your industrial marketplace is building digital twins, then it is already on the brink of creating a full-fledged metaverse. Besides having digital twins, a metaverse should even be populated with fully connected 3D objects that deliver an engaging experience.

Building a metaverse with a digital twin will help give your customers major entry points into experiencing an elevated digital experience. Many industrial service providers are already making sizable investments in creating digital twins and immersive virtual landscapes for their internal consumers and end-users.

Overall, by designing and implementing digital twins, industrial servicing enterprises are ready to model real-life spaces precisely. From manufacturing to automotive, smart cities, and healthcare, the role of digital twins cannot be downplayed now. That is why the industrial marketplaces and service providers that leverage digital twins at speed will be the disruptors instead of being the disrupted. These industrial players will unlock new frontiers of growth in ways that are beyond imagination.

Digital Twins And Their Impacts On Industry 4.0

Today, metaverses are discussed at length – especially in the context of industry 4.0, which is characterized by new-age manufacturing paradigms, automation, and data analytics. If digital twins are implemented at scale and speed, they will be at the core of accelerating the pace of transformation that defines in Industry 4.0.

After all, digital twins have successfully changed the traditional approach of build-first-tweak-later that is commonplace in the industrial landscape. When talking in the context of a metaverse, a digital twin will help create a virtual-powered design process with fast-paced technological advancements. These design processes will help usher in a new era of dynamic systems and living equipment. By offering a digital replica of machinery, digital twins will help operators:

- Discover performance roadblocks

- Uncover its unique features and potential

- Analyze future failures proactively

- Optimize its performance in real time with updates

Uncover The Next Big Digital Twin-Powered Industrial Revolution With Flexsin

If your industrial marketplace is poised to be disrupted by digital twins, then your business should make the first move. And by embracing digital twins, your business will also take the first concrete step toward materializing its metaverse and converging the real world with the virtual one. If your business is ready to design and deploy a digital twin but lacks the expertise, then we, at Flexsin, will help. We are a metaverse development company that can help you design digital twins, build DApps, and deploy multiple digital products. That way, together, we will help define your business’s metaverse and harness multiple growth possibilities.

Vishal

Vishal